2021年9月2日に、特別研究支援者のAkila Siriweeraさんが「SMALABO MINAMISOMA」を見学したレポートです。

SMALABO MINAMISOMA https://smartfactorylabo.com/minamisoma/

Report of the Company Visit

Attendee: Dr. Akila Siriweera

Place: ROBOTCOM & FA.COM, MINAMISOMA

Date visited: 2021/9/2

Company introduction

ROBOTCOM & FA.COM (R&F.COM) is a company with expertise in designing, developing, and maintaining smart factories for across the globe and clients who are seeking advanced robotics involving production lines, supply chain management, and factory automation. The R&F.COM is collaborating with the Aizu Research Cluster for robots (Arc-Robot) of the University of Aizu (UoA) under a project funded by the NEDO, Japan and work at the newly built manufacturing facilities at Minamisoma, Fukushima. Therefore, they invited us to have a factory visit and discussion for the collaboration. Arc-Robot lead by Professor Keitaro Naruse and Professor Makoto Yashiro visited the R&F.COM on 2nd September 2021. This report is based on that visit.

We visited R&F.COM at 13.30 and ended at 16.30. In the beginning, we entered their reception and had a preliminary presentation about the day. Next, R&F.COM conducted visits to the smart robots laboratory and manufacturing facility and discussed their R&D requirements.

Smart Robots Laboratory

Smart robots laboratory equipped with series of diverse R&D robots for various use cases.

Here below is a brief introduction of displayed robots.

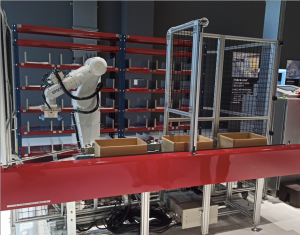

Fig. 2. Pallet/ tray sorting and arranging robot

Fig. 2. Pallet/ tray sorting and arranging robot

Pallets/ Trays arranging robot

This robot is designed and developed to move and align pallets or trays for a production line, which requires adjusting end-user efficiency concerning the dynamic ordering or demanding of the facility.

Fig. 3. Apparel processing robot

Fig. 3. Apparel processing robot

Smooth & flexible Apparel packing & sorting robot

This robot specializes in the smooth handling of inclining or soft materials/ objects, such as clothes and ordering/ sorting them for pre-requested orders.

Fig. 4. Edge-computing framework for real time monitoring and simulation

Fig. 4. Edge-computing framework for real time monitoring and simulation

Edge-computing framework for real-time factory monitoring and simulation

The system is designed for digital simulation for factory production lines and real-time monitoring, a key milestone for the revolutionary digital twin.

Fig. 5. Robot for meat product processing for bento

Fig. 5. Robot for meat product processing for bento

Cooked meat/ food products handling robot

This line is designed and developed for operating cooked meat/ food products for bento processing plants. This can smoothly handle individual food items concerning the particular processing line of the bento.

Fig. 6. Delivery robot and robot arm

Fig. 6. Delivery robot and robot arm

Delivery robot & robot arm

Delivery robots deliver particular items, and the robot arms are designed to collect items concerning the dynamic and custom requirements of the given cell and to carefully place them.

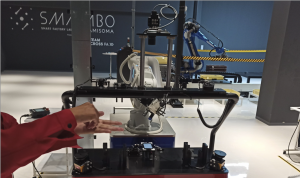

Fig. 7. Smart phone assembling robot

Fig. 7. Smart phone assembling robot

Smartphone assembling robot

This robot specializes in manipulating the smartphone manufacturing process since the chips and components assembling. That can smoothly handle arrays of screws to different sizes of nuts and bolts.

Fig. 8. Smart phone tester robot

Fig. 8. Smart phone tester robot

Smartphone test case handling robot

This robot is specialized in conducting pre-defined software related test cases related to the given smartphone.

Manufacturing Facility

The manufacturing facilities are designed and developed for conducting cutting-edge R&D on smart robots and their accessories, and for manufacturing custom smart robots and production lines for factories.

Two-third of the facilities is dedicated to manufacturing custom smart robots and production lines for factories, as shown in Fig. 9. Data management conducts as two-layered industry-grade firewalls. The two-layer comprises the edge computing layer and the central cloud layer.

Next, as shown in Fig. 10, the other part of the factory dedicates to the R&D of smart robots and accessories. Moreover, manufacturing cutting edge tools and accessories are one of major jobs. Nevertheless, they use hybrid power system, local power supply and solar power supply. Therefore, it has real time surveillance system to balance power consumption under pre-defined factors.

Fig. 9. Main floor of the Manufacturing facility

Fig. 9. Main floor of the Manufacturing facility

Fig. 10. Smart robot R&D, accessory designing & development, and power management system

Fig. 10. Smart robot R&D, accessory designing & development, and power management systemSummary

The visit's main objectives were to learn the various proceedings happening in the manufacturing facility of R&F.COM, Minamisoma, and to discuss the progress of collaboration works. Furthermore, the factory visit allowed us to see various real-world factory system development sections and to learn parts of their department, machinery, and ongoing projects. The most exciting part of the visit was the first-hand experience in the manufacturing facility of factory automation systems. Moreover, R&F.COM expects to start their operation for the cutting-edge real-world factory robotics system requirements.